Thinking about how to start a paper cup making machine business from home? If you’ve been searching for a clean, eco-friendly, and profitable small business idea, starting a paper cup manufacturing business in India could be just the answer. With the government phasing out single-use plastics and supporting small production units, this is one of the hottest business trends for 2025.

Every morning, people reach for a disposable paper cup for their tea, coffee, or juice, and in the evenings, the same cups make ice cream treats possible. Ever burned your tongue on hot chai in a paper glass? That’s part of the magic—these cups hold temperature and prevent leaks. Today, I’ll share everything you need to know about the process, machines, profits, and steps for starting this business, using my own experience and insights.

Why Paper Cup Business is Booming in 2025

Paper cups aren’t just about convenience—they’re about solving real problems. Plastic waste is a global headache, and traditional plastic cups take 20 to 500 years to decompose. These plastics poison our soil, harm crops, and damage the environment far longer than you’d think.

Why is this business trending right now?

- Plastics banned for most food and drink uses since August 2021.

- Paper cup business government subsidy up to 35% to start, plus loans available.

- Demand exploding in tea shops, juice vendors, malls, and grocery stores.

- Consumers more eco-conscious than ever.

- Entry cost is accessible; can be started from home or with small commercial space.

Summary of key environmental factors:

- Plastic takes 20–500 years to decompose

- Chokes soil, harming crops and environment

- Plastic cup/plate/bag ban by Indian government in August 2021

- Loans with up to 35% subsidy to boost paper alternatives

With all this support and a market that’s only growing, it’s no surprise the paper cup business is picking up steam in India. Let’s get down to what it takes to get started.

Paper Cup Manufacturing: Materials and Step-by-Step Machine Process

Raw Materials Needed

To produce paper cups, only two ingredients matter:

- Paper cup blanks: These are the pre-cut, printed sheets that form the body of the cup.

- Paper cup bottoms: The round discs that seal the base.

You can buy both blanks and bottoms directly from paper suppliers or manufacturing companies. Sourcing is straightforward, and pricing is competitive.

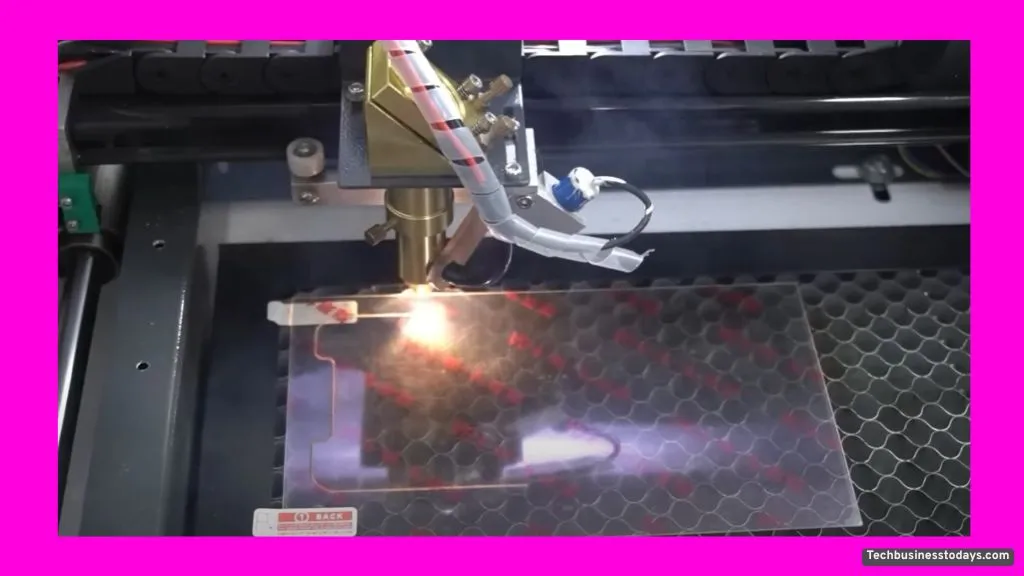

How the Paper Cup Making Machine Works

Here’s how these magical cups get made, start to finish, using a modern, fully automatic paper cup machine:

- Feeder Station

I load the paper cup blanks into the feeder. These sheets are easily available in the market. - Folding Station

The machine folds each blank into a round tube—this becomes the basic shape of the cup. - Rotary Table Transfer

The tube is transferred automatically to the next stage for base sealing. - Bottom Attachment & Punching

The pre-cut bottom disc is attached to the tube using a roll loaded into the machine. The punching station fixes the base tightly. - Three-Stage Pre-Heating

The machine gently heats the entire cup at three stations. This step ensures a perfect seal between the sides and base, keeping cups leak-proof and sturdy. - Nurling Station

Here, the machine presses and firmly seals the joint so hot liquids won’t leak. - Earling Station

Now, the top edge gets a thickened ring. This gives the cup its sturdiness and stops it from sticking to drinks.

Process flow at a glance:

- Paper blanks loaded → Tube shaped → Base attached → Pre-heated → Sealed → Rim rolled → Cup ejected, ready to use

A simple diagram or photos of each step can help visualize, but even without them, the process is logical.

Choosing the Right Paper Cup Making Machine

Machine Models and Their Output

If you’re wondering how to start a paper cup making machine business from home with the best results, let’s talk machines.

Top models for 2025:

- Pasi 75: Makes up to 4000 cups per hour.

- PC5: Produces between 5000 and 5500 cups per hour.

Machine Features and Specs

- Cup Sizes: From small 30 ml shots to 350 ml (juice, coffee, or even small soup servings).

- Bottom diameter: 30 to 60 mm; suits many types of drinks.

- Paper Thickness: 140 to 270 GSM (grams per square meter), so you can control how sturdy your cups are.

- Power Needs: Each machine needs about 3.5 kW, so plan for a dedicated electricity connection.

The cup size changes by swapping out the die (a simple process), and you can source paper blanks in the GSM you want to adjust strength and cost.

Permits, Barcodes, and Compliance

Like any food-contact business, you need to follow a few simple rules. Here’s what I needed when I was getting started:

Essential Licenses and Registrations:

- GST registration

- Udyam (MSME) Registration

- Factory license (if you scale up or take a large rental unit)

Summary checklist:

- GST registration

- Udyam/MSME registration

- Factory license (optional, as needed)

- Barcodes from Quickbarcode.com (10% off with “NEWTECHINDIA”)

- Apply for PMEGP/PM Mudra business loans for up to 35% subsidy

If you live in Gurugram, Faridabad, or Palwal (Haryana), connecting with government officials like Mr. Krishna Singh at the MSME department helps make your paperwork smooth. These officers can provide all the scheme and subsidy details you’ll need.

The Market: Demand and Business Potential for Paper Cups

In 2025, almost every chaiwala, juice center, mall, or supermarket uses paper cups. You can’t escape them—from small tea stalls on the road to fancy retail stores in big cities, demand is everywhere.

This is because paper cups are single-use but recyclable. After use, they’re sent to paper recycling plants and turned into new products, so hardly any waste ends up in landfills.

Environmental Benefits

- No lingering waste like plastics

- Protects soil and improves recycling rates

How to Test the Market

Here’s something I tried before buying my own machine: buy ready-made cups from manufacturers and supply them to local shops. This way, I built relationships, learned about pricing and demand, and saw how quickly I could move stock. Once I got the hang of it, investing in a machine made sense—I knew what my local demand was and already had customers lined up.

Why Start in 2025?

If you want to know how to start a paper cup making machine business in India, or even from home, there’s never been a better time:

- The ban on plastic cups has been enforced for two years, with demand rapidly rising.

- The government supports the switch to paper with loans and subsidies.

- People want cleaner, greener options.

For those who like success stories, many local suppliers I know began this way—testing demand, learning the ropes, and then starting their own units when they felt confident.

Paper Cup Business Profit Margin and Investment: From Cost to Earnings

People always ask about profit. Here’s the breakdown, using recent real-world numbers and the latest machines on the market.

Machine and Setup Costs

- A quality paper cup making machine costs around ₹6.5 lakh and above (excluding GST).

- Including raw materials, electricity, basic furniture, and workspace, you’ll need a total investment around ₹9–10 lakh for a small, organized setup.

Production and Output

- Hourly Output: 4000–5500 cups (depending on machine)

- Per day (8 hours): 30,000–32,000 cups

Paper Cup Business Profit Calcula

| Item | Qty / Rate | Total |

|---|---|---|

| Paper blank (per kg) | ₹90–95 / 900 cups | ₹0.10–0.11 |

| Bottom roll | ₹250 per kg / 3600 cups | ₹0.07 |

| Total cup cost | – | ₹0.20 |

| Wholesale price | – | ₹0.25 |

| Retail price | – | ₹0.30–0.40 |

So, for every cup produced, the profit margin ranges from 5 to 10 paise in wholesale, even more in retail.

If you run a single shift and sell all 30,000 cups per day at wholesale rates:

- Profit per cup = ₹0.05

- Daily profit = ₹1,500

- Monthly = ₹40,000–45,000

Some factories run two shifts for double output and profit. Machines run reliably all day with basic maintenance.

Key tips for new entrants:

- Start by reselling cups from wholesalers to test your market.

- Move to your own machine only after building experience and customer base.

- Keep expenses in check, especially overheads in the beginning.

Government Subsidies and Support

Getting funding is simple if you have your documents ready. Through Paper cup business government subsidy programs like PMEGP or PM Mudra Loan, you can get a loan for up to 65% of your project cost, with a 35% subsidy to reduce repayment amount.

MSME departments in each state, and especially in Haryana (Gurugram, Faridabad, Palwal), can guide you with current schemes. Connecting with an official like Mr. Krishna Singh makes things easier.

You can reach out directly or use links in the resources below for direct application access.

Step-by-Step: How to Start a Paper Cup Making Machine Business from Home

- Research your local demand by visiting tea stalls, juice centers, and small eateries.

- Procure and resell cups from an existing paper cup manufacturer first, to get a feel for the market.

- Register your business with GST and Udyam (MSME).

- Get barcodes from a trusted site like Quickbarcode.com (use the “NEWTECHINDIA” code).

- Apply for government funding, using PMEGP or PM Mudra schemes if needed.

- Source your paper blanks and bottoms from reliable companies.

- Buy your machine from a dependable supplier (see fully automatic machine options here).

- Install and test-run the machine (ensure proper 3.5 kW power supply).

- Market your product to the shops and vendors you’ve already talked to.

- Track all earnings and costs for ongoing Paper cup business profit calculas and to optimize pricing.

Conclusion

When family, friends, or fellow entrepreneurs ask me how to start a paper cup making machine business from home, I always say—this is one of the most rewarding, future-proof businesses you can begin right now.

यह भी पढ़ें.