If you’ve wondered how to start a mobile tempered glass cutting machine business in India, you’re not alone. Whether you own a repair shop, a small manufacturing unit, or just want to get into the booming accessories market, understanding the process, costs, and tools is vital. Let me take you through everything you need to get going, including insider details about the most popular machines, pricing, daily operations, and all-important after-sales support.

With the rise in smartphones, the demand for tempered glass screen protectors, camera lens films, and custom mobile stickers has never been higher. Shops and micro-entrepreneurs everywhere want to meet this demand while keeping costs low and service quality high. If that sounds like you, keep reading.

Overview of the Mobile Sticker & Film Cutting Machine

The heart of starting a mobile tempered glass business is the cutting machine itself. One of the most talked-about models right now is the 207 film and sticker cutting machine. Its popularity has crossed borders, attracting attention for its reliability and user-friendly design.

Why Is Model 207 So Popular?

Model 207 stands out for several reasons:

- Ease of use: Minimal parts and simple operations mean you don’t need a technical background.

- Low maintenance: You spend less time and money on upkeep.

- Strong support: Warranty and guarantee are standard, adding peace of mind for new business owners.

The big touchscreen makes working smoother, letting you operate much like on a smartphone. The touch panel is responsive, and if you ever need help, spare parts and servicing are easy to access.

What Comes in the Box?

When you buy a machine like the 207, you get much more than just the hardware. Here’s what’s included:

- User manual and setup guide for quick start and troubleshooting

- Special rubber accessories for stable cutting

- Tub with consumable liquid (“blood”) that lasts for multiple cuts (saves you roughly ₹2,500 compared to buying separately)

- High-quality wipe cloth for cleaning surfaces and films

- Tweezers for handling cut films with care

- Adapter to power the machine out of the box

- Warranty card and reliable support for peace of mind

Repairs and service are just as simple. If the touchscreen cracks, the display dims, or any other issue pops up, you won’t need to replace the whole machine. Cost-effective repairs and a steady supply of parts mean your investment lasts.

Connectivity and Setup Process

Getting started is as easy as powering up your phone. Here’s how to set up your mobile tempered glass making machine for daily work:

- Connect to WiFi or Mobile Hotspot:

The machine’s interface is like a smartphone. Go to the settings, select your WiFi or hotspot, and connect. If your shop doesn’t have WiFi, just use your mobile hotspot. - Understand the Operating System:

The machine uses a familiar layout, so if you’ve ever used a smartphone, you’ll pick this up fast. You can scroll, select, and set up everything using the touchscreen. - Processor Matters More Than Screen Size:

I found that the size of the screen matters less than having a good processor. A solid processor means the machine runs cuts quickly and precisely, without lag. This boosts daily productivity and lets you serve more clients.

Features and Functionalities: What Can You Cut?

This machine isn’t just for mobile screens. It’s a versatile tool packed with options, covering nearly every need in the mobile accessories market.

Types of Items You Can Cut

Here’s what you can cut using a modern mobile tempered glass manufacturing machine:

- Tempered glass screen protectors for all major phones

- Films and stickers for watches, tablets, smartwatches, and camera lens covers

- Full screen, back cover, side edge, and specialty cutouts

Need to make a cutout for the speaker, sensor, or front camera? The machine has ready-made templates, and if your device isn’t listed, you can request a custom profile.

Massive Library of Device Models

Keeping inventory for every new phone is tough, so this machine includes templates for over 40,000 mobile device models out of the box. It supports all big brands:

- Samsung

- iPhone

- Vivo

- Oppo

- Realme

- Mi

- Redmi

- And many more, for every year and variant

Whenever a new phone launches, updates keep your machine ready. If you need a model that’s missing, the seller can provide it in 20 to 30 days. That flexibility is rare.

Customization and Cutting Precision

The system lets you:

- Select the precise model and variant you want to cut for

- Adjust for thin, standard, or thick film/tempered glass

- Set pressure and cut options for different surfaces (front, back, side)

- Add custom images, logos, or photos for printed stickers

Want a matte finish sticker? It’s a click away. Need a photo for the back cover? Upload and cut in one workflow.

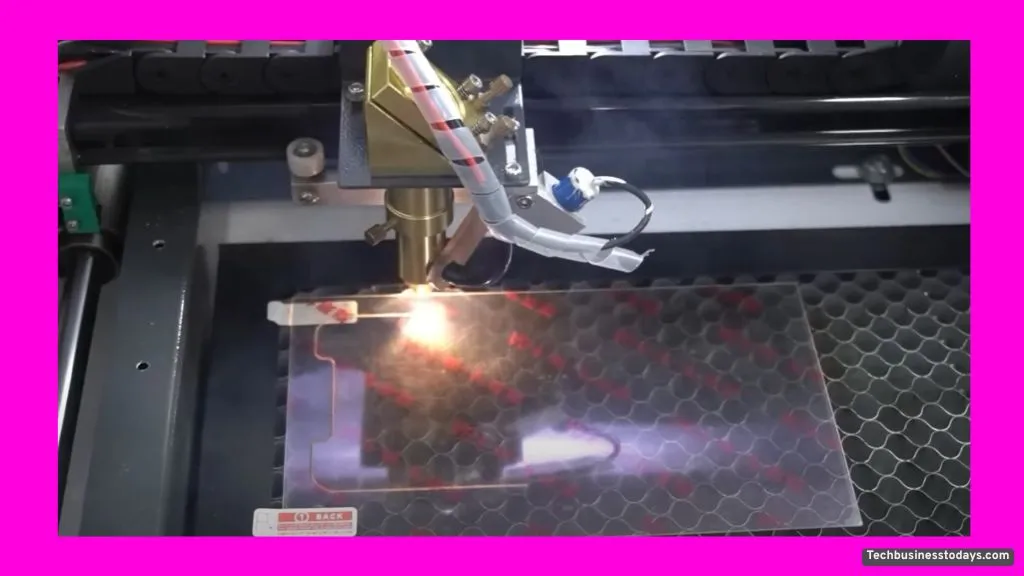

How Actual Cutting Works

Here’s what a cutting workflow looks like:

- Select device model and variant

- Set cutting parameters (thickness, pressure, area)

- Place the sheet onto the work surface and calibrate

- Hit start. The machine takes care of the rest.

Choose from preloaded cuts or add your own. The machine adjusts automatically. For a standard mobile screen protector, expect a finished cut in about 6 seconds. That’s up to 10 clients in just a few minutes.

Consumables and Accessories: What You Get and How To Reorder

Your Mobile Tempered Glass manufacturing machine comes with everything needed for dozens of cuts:

- The “extra blood” cutting fluid, which usually costs about ₹2,500 outside, is included at no extra charge

- Cleaning wipes, high-quality tools, and other accessories support smooth operation

- Tweezers and manual guides are there for those first-time users

Repair, Maintenance, and After-Sales Support

A big worry when you buy a new machine is: what if something goes wrong? Thankfully, support for these machines matches their robust build.

Common Repair Scenarios

- Touchscreen issues after accidental drops or rough use

- Screen or display problems causing clarity to fade or images to flicker

- Physical damage such as parts breaking due to falls or impacts

I’ve seen plenty of users get stuck with other machines after accidents or wear and tear, but with the 207 and similar models, you don’t need to worry.

Cost and Process

Repairs are usually quick and cost far less than replacing a whole machine. Key benefits:

- Spare parts always available from the supplier

- Warranty covers most issues, giving you financial security

- Repairs don’t take long, and you’re rarely without your machine for more than a day or two

This kind of support is what makes these machines a favorite for anyone asking about How to start mobile tempered glass cutting machine business in India.

Long-Term Peace of Mind

Once you buy your machine, you’re not alone. From software updates to hardware repairs, long-term support keeps your operation running smoothly. You also avoid the risk of having to throw away your investment—almost everything is replaceable.

Practical Applications and Use Cases

When you ask how to start mobile tempered glass cutting machine business in India, you have to consider who needs this service and how best to serve them.

Who Benefits from a Mobile Tempered Glass Manufacturing Machine?

- Mobile repair shop owners: Increase revenue by offering on-the-spot custom screen protectors and stickers.

- Small-scale manufacturers: Produce a variety of films and mobile covers for resale or private labeling.

- Accessory retailers: Keep inventory minimal and always meet customer needs, no matter the phone.

- Online resellers: Fulfill custom orders for a wide range of devices and gadgets.

Everyday Items Cut

- Mobile phone screens (front and back)

- Camera lens protective covers

- Watch and wearable device stickers

- Printed photo stickers for personal or promotional use

Accuracy and Speed Matter

The best machines cut cleanly in about 6 seconds. The software-driven blade delivers a professional finish with sharp edges and exact cutouts for cameras, sensors, and speakers. When customers see the results, repeat business is almost certain.

Need stickers with photos or company logos? That’s no problem. Whatever your customers imagine, you can deliver on demand.

Ordering, Pricing, and Company Information

If you’re ready to order, here’s what to expect:

Mobile Tempered Glass Manufacturing Machine Price

The main machine featured here is priced around ₹40,000. Given the included templates, support, updates, and physical accessories, it beats most competitors. For direct comparison, similar machines abroad or from other brands cost more or don’t offer Indian support.

- Custom models: If your model isn’t already programmed, you can request it and have it added in about 20-30 days.

- Cutting fees: With this machine, you usually get cutting charges for free at first, while many in the market charge extra for the same feature.

If you want a full price breakdown or want to compare with Toughened glass Manufacturing Plant Cost in India, reach out for the latest rates.

Conclusion

To sum up what I’ve found:

- Huge model database: Over 40,000 device types supported

- Custom on-demand service: No more saying “we don’t have this size”

- Fast, accurate cutting: Save time, serve more clients, and impress with precision

- Strong warranty and support: Parts, updates, and repairs are always nearby

- Essential accessories included: Consumables, manuals, and all tools you’ll need

If you want to know more about how to start mobile tempered glass cutting machine business in India, or want a custom demo, let me know. I’m happy to make more content on this topic or help you get your new venture off the ground.

यह भी पढ़ें.