Starting a business from home isn’t just a trend—it’s now a real way to build your future and support your family. One idea growing fast in India is the t-shirt printing business. Maybe you’ve seen printed tees at local stores or online and wondered how you can make and sell them yourself. The truth is, you can launch your own t-shirt printing business using a heat press machine right from your living room or garage.

Whether you want independent income, a side hustle, or a full-time gig, I’ll show you exactly how to start a T-shirt heat press machine business in India with simple tools and straightforward steps. I’ll walk you through the process, costs, materials, and tips to help you make your first sale and keep growing.

Why T-shirt Printing is a Great Business for Beginners

T-shirt printing lets you mix creativity with business, even if you have little experience or money to start. Most people love custom t-shirts for events, businesses, and social groups. If you plan it well, you can earn a steady income over time—some makers even make ₹1,00,000 per month or more.

The biggest advantage of this business? You can start small.

You only need some basic equipment, a little room at home, and a plan to find your first customers. There’s no need to rent a shop or hire staff at the start. Using a t-shirt printing machine for a small business is simple to learn. Plus, you’ll be in control of your time, designs, and profits.

Understanding T-shirt Printing: Which Method Should I Use?

Choosing the right printing method is the first key step. The best option for beginners in India is heat transfer printing. It’s straightforward, affordable, and doesn’t need advanced training. Let’s unpack what you need to know.

Heat Transfer Printing

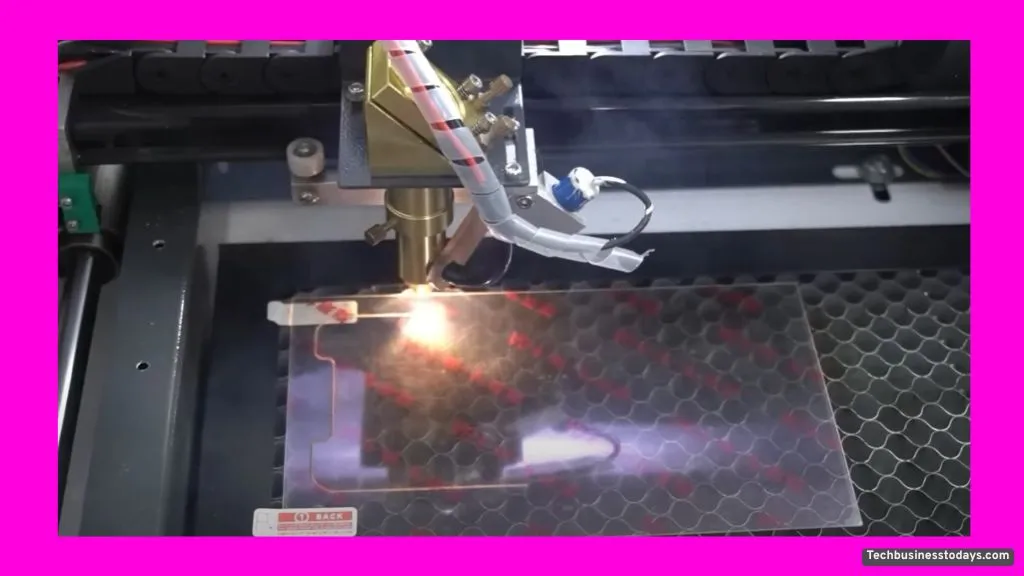

Heat transfer printing works by transferring a design from a special transfer paper onto a t-shirt using heat and pressure. You need a heat press machine, the right transfer paper, and a home printer to print your designs.

Here’s how the process goes:

- Design Creation: Make or edit your t-shirt design using simple software.

- Printing: Print the design in reverse (mirror image) onto transfer paper.

- Pressing: Place the transfer paper on a blank t-shirt and use the heat press to transfer the ink.

Most home-based businesses use Adobe Photoshop or CorelDRAW for their designs. They let you create logos, texts, and images that stand out. You can check out the Adobe website for more Adobe Photoshop info or see CorelDRAW for design tips.

Materials for heat press t-shirt printing:

- Blank cotton t-shirts (white and colored)

- Heat transfer paper (match your printer type: inkjet or laser)

- Heat press machine

- Standard color printer (inkjet is most common)

- Scissors or a cutter (for trimming designs)

- Adobe Photoshop, CorelDRAW, or similar software

Other Printing Methods (Short Overview)

There are many advanced ways, like screen printing and direct-to-garment (DTG). These work well for large businesses but need more space, more equipment, and higher investment. For how to start a t-shirt heat press machine business from home, stick with heat transfer printing at first. It’s enough for local and online sales and keeps your setup easy.

Equipment and Starting Costs: What You Need to Get Started

If you want to know how to start a t-shirt heat press machine business in India in your spare room, you’ll need a few main things. Good news—the basics are easy to find both online and in big cities.

Must-have Machines and Tools

- Heat press machine: The heart of your business. Get a reliable model with a clear heat and timer setting. For a t-shirt printing machine for small business prices, expect to pay anywhere from ₹10,000 to ₹30,000 depending on size and brand.

- T-shirt press machine and printer: Use a simple inkjet printer to print on transfer paper. Multifunction models are affordable and easy to maintain.

- Starter kit: Many suppliers offer a t-shirt printing machine starter kit, which includes the heat press, sheets of transfer paper, blank t-shirts, and sometimes basic design templates.

What Does It Cost to Start?

Here’s a breakdown of the typical starting prices:

- Heat press machine: ₹10,000–₹30,000

- Standard color printer: ₹5,000–₹10,000

- Transfer paper pack: ₹500–₹2,000 for 50–100 sheets

- Blank t-shirts: Bulk purchase brings costs down (₹80–₹250 each)

- Software (free trials or paid versions): Varies; many options are under ₹2,000 per month or a one-time payment.

Steps for Buying Equipment

- Research brands and models known for durability.

- Check if the seller offers customer support and demo videos.

- Compare prices for heat press machines and printers online and in local markets.

- Start with a small pack of each material to test quality before buying in bulk.

Don’t forget you will need a local trade license and GST registration once you’re ready to sell as a business. These costs can vary by city, but it’s a must for building a legal foundation and trust.

Setting Up and Running Your Home-Based T-shirt Printing Business

Organizing your operation right helps you save time and avoid mistakes. Here’s what’s important for making a smooth start at home.

Setting Up Your Workspace

A successful home-based t-shirt printing setup doesn’t need a lot of space. I suggest:

- A sturdy table or workbench for your heat press machine

- A separate shelf for organizing transfer papers, blank shirts, and finished prints

- Good ventilation for safety, especially when using the press regularly

- Easy access power outlets for your press and printer

Keep things tidy—an efficient workspace means faster and neater work, with less chance of damaging shirts.

Designing and Printing Your Shirts

- Begin by sketching simple designs or using free templates.

- Open your design software (Adobe Photoshop, CorelDRAW, or others) and size your art to match the shirt area.

- Print a test page first to check colors and alignment.

- Trim excess paper from your print so edges don’t show up on the shirt.

- Use the heat press as directed—most t-shirt presses need to reach 160–180°C and require 10–20 seconds of pressing.

- Peel the transfer paper at the recommended temperature (hot or cold peel).

Check each shirt for strong color and alignment before giving it to customers.

Legal Setup and Documentation

- Apply for a local trade license to show you’re a registered small business.

- Register for GST so you can sell online or to retailers without worries.

- If you want to start online, consider business bank accounts to keep income and expenses clear.

A clear legal base also makes it easy to expand or get support—whether selling in shops or online.

Marketing and Selling Your Custom T-shirts

Selling is where your effort starts to pay off. With the right approach, you’ll find loyal customers both in your neighborhood and across India.

Local and Online Selling Options

- Local markets: Sell to neighbors, clubs, and small stores. Many need custom t-shirts for events, teams, or businesses. Visit local markets or festivals to set up a stall.

- Online platforms: List your tees on websites like Amazon, Flipkart, or your own online store. Social media channels like Instagram and WhatsApp are powerful for reaching young buyers.

- Word-of-mouth: Happy customers bring referrals. Offer good service and ask satisfied buyers to spread the word or share pictures.

Price Your Products and Predict Profits

When setting prices, include:

- Cost of blank shirts and transfer paper (roughly ₹100–₹250 per shirt)

- Printing and labor (time and wear on the machine)

- Packaging and delivery (if sending items online)

A fair selling price for good-quality custom shirts ranges from ₹300 to ₹600.

Example profit: For each t-shirt, profit often ranges from ₹100 to ₹300 after costs. If you sell just 10 shirts per day, you could earn up to ₹100,000 per month with consistent sales and smart marketing.

Growing Your Customer Base

- Create an Instagram page and post photos of your designs.

- Offer limited-time discounts for new customers to encourage trial orders.

- Run contests or giveaways to boost your reach.

- Join local WhatsApp groups or Facebook communities focused on small business.

- Ask for feedback and use it to improve quality.

Tips From My Experience: How to Keep Growing

After spending time in this business, I’ve learned a few lessons that can save you both time and money. Here are my top takeaways for those who want to know how to start a t-shirt heat press machine business online or offline:

- Start simple, then expand your designs and products as you get comfortable.

- Always do a test print before printing many shirts—mistakes multiply fast.

- Keep your workspace clean and organized.

- Don’t rush to cut prices; focus on value and quality to build a following.

- Reinvest part of your profit into better machines or higher-quality supplies.

Stay patient, keep learning new design tricks, and ask customers for suggestions. Each happy buyer is a step toward more orders and a stronger brand.

Conclusion

Launching a t-shirt printing business from home is simple, affordable, and open to anyone with a creative spark and the willingness to learn. By getting the right equipment, following the process, and building strong local or online connections, you can go from your first design to a thriving microenterprise.

यह भी पढ़ें.